When it comes to achieving unparalleled precision in cutting through hard materials, the best Diamond Wire Cutting Machines stand out as the champions of the industry. These machines, equipped with diamond-impregnated wire, offer a level of precision and efficiency that traditional cutting methods simply cannot match. Among the leading brands in this sector, Shine has consistently been at the forefront, delivering cutting-edge technology and robust performance through its range of diamond wire cutting machines.

The versatility of Shine’s diamond wire cutting machines means they can be used across a wide range of applications, from construction to manufacturing, without compromising on quality and precision. The key to their success lies in the innovative design that combines speed, precision, and durability, making them a top choice for professionals seeking the best Diamond Wire Cutting Machines on the market.

Choosing the right diamond wire cutting machine can be a daunting task, given the myriad of options available. However, focusing on a few critical features such as cutting speed, wire lifespan, machine robustness, and after-sales support can help narrow down the choices. Shine machines, for instance, excel in all these areas, providing a compelling option for those in search of the best in the business.

- Unmatched Precision: The diamond wire technology allows for cuts with exceptional accuracy.

- Versatility: Capable of cutting through a variety of materials, including reinforced concrete, stone, and metal.

- Efficiency: Designed for rapid cutting without sacrificing quality, saving both time and resources.

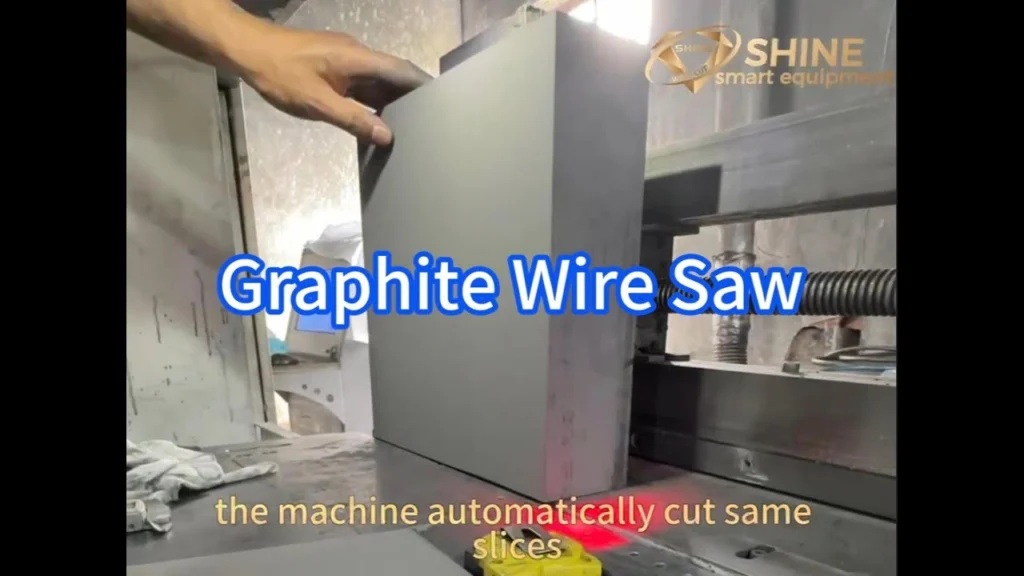

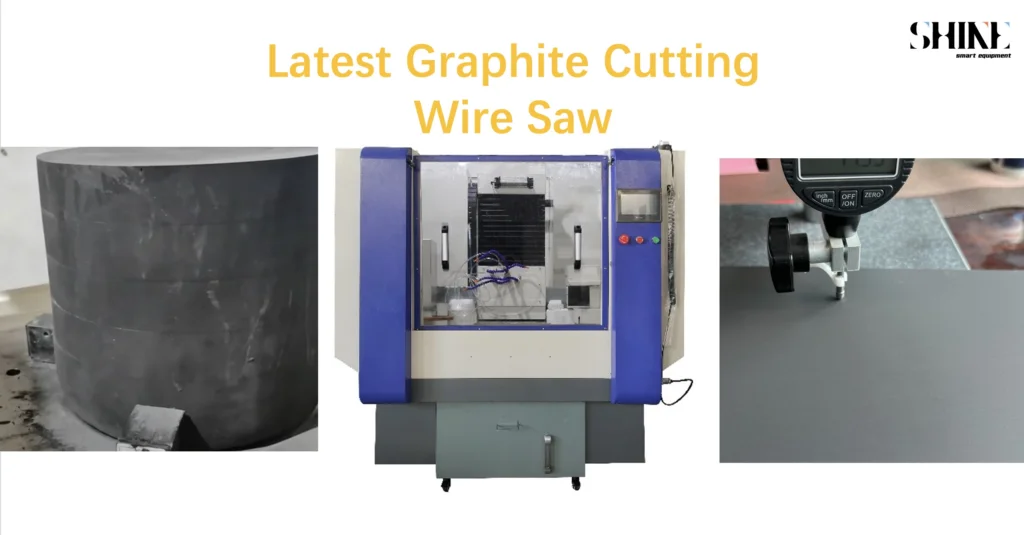

As we delve into the specifics, here are some of the top models from Shine that have set the standard for the best Diamond Wire Cutting Machines in the industry. Each model brings something unique to the table, catering to different needs and applications. Whether it’s for heavy-duty construction work or precise manufacturing processes, there’s a Shine machine tailored for the task.

In conclusion, the evolution of diamond wire cutting technology has been a game-changer in material cutting processes. With brands like Shine leading the charge, the future of precision cutting looks brighter than ever. As we continue to push the boundaries of what’s possible, the best Diamond Wire Cutting Machines will undoubtedly play a pivotal role in shaping the future of various industries.

Top 10 Best Diamond Wire Cutting Machines for Precision Cutting

Table of Contents

Introduction to Diamond Wire Cutting Technology

The world of material cutting has witnessed a revolutionary shift with the advent of diamond wire cutting technology. This cutting-edge advancement allows for precision cutting of a wide range of materials, from reinforced concrete to highly delicate silicon wafers. At the heart of this technology are the Best Diamond Wire Cutting Machines, designed to deliver unparalleled accuracy and efficiency. The key component, a wire impregnated with diamond segments, is capable of cutting through almost anything with minimal waste and incredible speed.

One brand that stands out in this innovative field is Shine, renowned for its commitment to quality and performance. The Best Diamond Wire Cutting Machines from Shine are not just tools; they are partners in precision, enabling industries to achieve flawless cuts that were once deemed impossible. The technology’s versatility extends from the construction industry, where it’s used for cutting through thick concrete, to the intricate world of semiconductor manufacturing, where precision is non-negotiable.

What sets the Best Diamond Wire Cutting Machines apart from traditional cutting methods? It’s their ability to maintain integrity and accuracy over long distances and through complex cuts. Whether it’s shaping a massive bridge or crafting a delicate jewelry piece, Shine’s diamond wire cutting machines ensure that every cut is a masterpiece of precision.

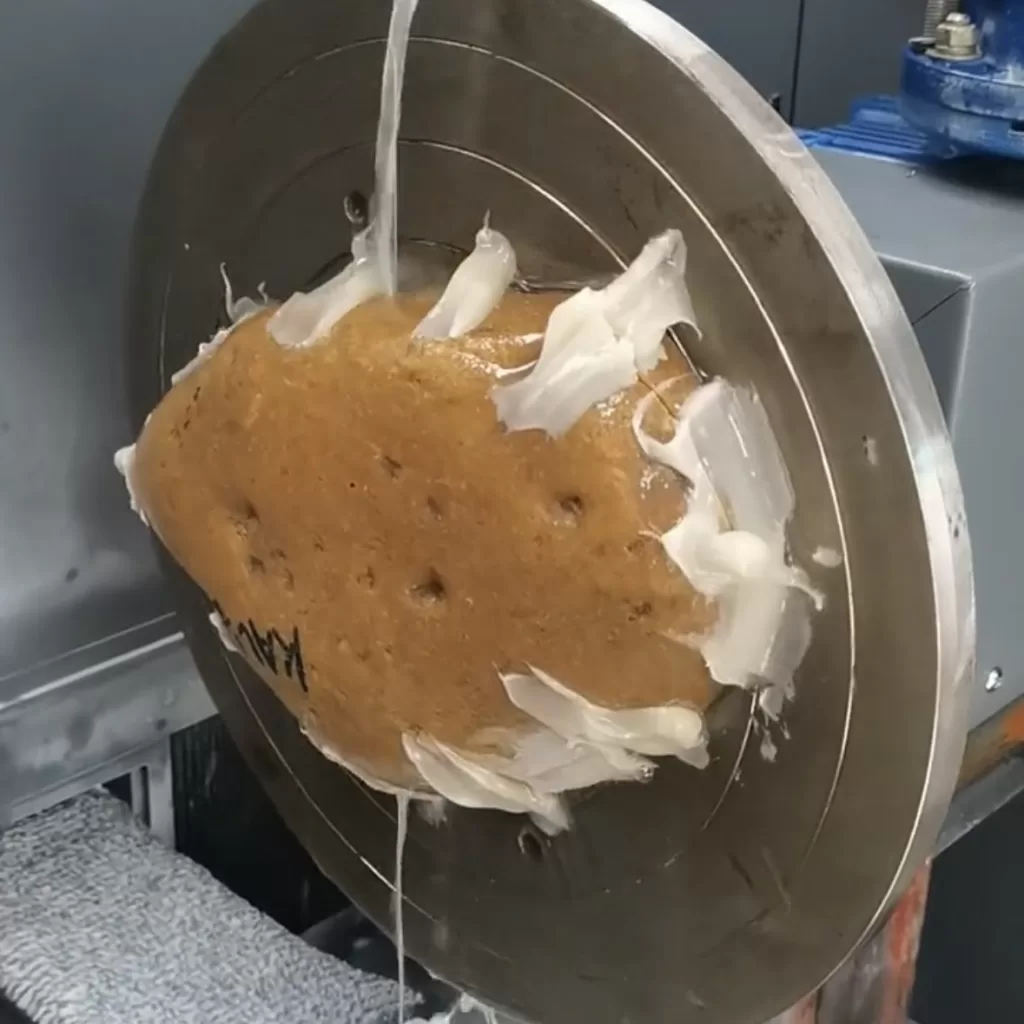

Understanding the mechanics behind these machines is crucial for appreciating their capability. The process involves guiding a wire coated with diamond segments at high speed around the material to be cut. As the wire moves, it abrades the material, slicing through it with minimal kerf and maximum efficiency. This method not only preserves the structural integrity of the material but also significantly reduces waste, making it a sustainable choice for modern manufacturing and construction practices.

In summary, the introduction of diamond wire cutting technology has been nothing short of a revolution, offering a blend of precision, efficiency, and versatility that traditional cutting methods cannot match. With brands like Shine leading the way, the future of cutting is not just about making incisions but about redefining the boundaries of what’s possible. As we delve deeper into the capabilities and applications of the Best Diamond Wire Cutting Machines, it’s clear that this technology is not just changing industries; it’s shaping the future.

Benefits of Using Diamond Wire Cutting Machines

The advent of diamond wire cutting machines has been a game-changer in the world of precision cutting. These machines, epitomized by the leading brand Shine, bring to the table a suite of benefits that significantly overshadow traditional cutting methods. Let’s delve into why these machines, particularly the Best Diamond Wire Cutting Machines from Shine, are becoming indispensable in various industrial applications.

First and foremost, the precision offered by Shine’s Best Diamond Wire Cutting Machines is unmatched. The ability to make clean, accurate cuts with minimal material wastage is a hallmark of these machines. This precision is not just about cutting accuracy; it also means less finishing work is required, saving both time and resources.

Another standout benefit is the versatility of these machines. Whether you’re working with granite, marble, silicon, or even reinforced concrete, the Best Diamond Wire Cutting Machines from Shine can handle it all. This versatility makes them a valuable asset across various sectors, including construction, manufacturing, and even art sculpture.

Efficiency is yet another area where these machines shine. With their high-speed cutting capability, Shine’s Diamond Wire Cutting Machines significantly reduce cutting time, thereby increasing productivity. This efficiency is not just in terms of speed but also in the machine’s ability to perform complex cuts that would otherwise require multiple conventional machines.

- Unmatched Precision: Ensures clean, accurate cuts with minimal finishing required.

- Versatility: Capable of cutting a wide range of materials across various industries.

- Efficiency: High-speed cutting capability increases productivity and enables complex cuts.

- Reduced Waste: Precise cuts mean less material wastage, contributing to cost savings and environmental sustainability.

- Safety: Advanced safety features protect operators from potential hazards associated with cutting processes.

In conclusion, the benefits of using Shine’s Best Diamond Wire Cutting Machines are clear. They offer an unparalleled combination of precision, versatility, and efficiency, making them a top choice for professionals seeking to elevate their cutting processes. As technology advances, we can only expect these machines to become even more indispensable in their respective industries.

Key Features to Consider When Choosing a Diamond Wire Cutting Machine

When it comes to selecting the Best Diamond Wire Cutting Machines, the process can be as intricate as the cutting tasks these machines perform. With the brand “Shine” leading the pack, there are several critical features to look out for to ensure you’re investing in a machine that not only meets but exceeds your expectations. Let’s dive into the core attributes that set the Best Diamond Wire Cutting Machines apart, particularly those from “Shine”.

Precision and Accuracy: The hallmark of any Best Diamond Wire Cutting Machine is its precision. “Shine” models are renowned for their ability to deliver cuts with impeccable accuracy, making them indispensable for industries where every millimeter counts.

Speed and Efficiency: Time is of the essence in any production environment. “Shine” diamond wire cutting machines are designed to maximize productivity, offering rapid cutting speeds without compromising on the quality of the cut.

Durability and Reliability: The industrial environment is demanding. Therefore, investing in a machine that stands the test of time is crucial. “Shine” machines are built to withstand rigorous use, ensuring long-term reliability and minimal downtime.

Versatility: The ability to cut through various materials with ease is a must-have feature. “Shine” machines excel in this area, capable of handling everything from stone to reinforced concrete, making them versatile tools in any toolkit.

User-Friendly Interface: Complex machinery shouldn’t come with a steep learning curve. “Shine” understands this, equipping their diamond wire cutting machines with intuitive controls and interfaces that simplify operation for users of all skill levels.

Safety Features: Safety can never be overstated. With advanced safety features, “Shine” ensures that operators are protected at all times, making their machines not only effective but also safe to use in any setting.

After-Sales Support: The relationship between buyer and manufacturer doesn’t end at purchase. “Shine” provides exemplary after-sales support, ensuring that you have access to maintenance and assistance whenever needed.

Choosing the Best Diamond Wire Cutting Machine is a decision that should be made with careful consideration of the features that matter most to your operational needs. “Shine” offers a range of machines that embody these key features, making them a top choice for professionals seeking precision, efficiency, and reliability.

Top 5 Diamond Wire Cutting Machines for the Construction Industry

When it comes to the construction industry, precision and efficiency in cutting materials are non-negotiable. With the advent of diamond wire cutting technology, the game has changed for the better. Among the plethora of options available in the market, finding the Best Diamond Wire Cutting Machines can be quite a task. However, one brand that consistently shines through is Shine. Known for their unparalleled precision and durability, Shine’s diamond wire cutting machines have become a go-to for construction professionals. Here, we delve into the top 5 Best Diamond Wire Cutting Machines specifically designed for the construction industry, brought to you by Shine.

- Shine UltraCut 100: Leading the pack is the UltraCut 100, renowned for its high-speed cutting capability and minimal material wastage. Its robust design makes it ideal for heavy-duty construction work, ensuring precision in every cut.

- Shine PrecisionMaster 300: Next on the list is the PrecisionMaster 300. As the name suggests, this machine is all about providing the utmost precision. It’s perfect for intricate cutting tasks where every millimeter counts, making it a favorite among construction professionals.

- Shine PowerFlex 500: The PowerFlex 500 stands out for its flexibility and ease of use in challenging cutting scenarios. Equipped with advanced technology, it can cut through the toughest materials with ease, making it a versatile tool in the construction industry.

- Shine MegaForce 700: Known for its durability and power, the MegaForce 700 is designed to handle the most demanding cutting jobs. Its high-performance cutting system ensures efficiency and speed, reducing project timelines significantly.

- Shine EcoSmart 900: Rounding off the list is the EcoSmart 900, which combines eco-friendly features with cutting-edge technology. It’s designed for construction professionals who are looking to reduce their carbon footprint without compromising on cutting quality.

In conclusion, when it comes to finding the Best Diamond Wire Cutting Machines for the construction industry, Shine stands out with its range of high-quality, durable, and precise machines. Whether you’re looking for speed, precision, flexibility, power, or eco-friendliness, Shine has a machine that fits the bill. Investing in a Shine diamond wire cutting machine means investing in the future of construction, ensuring that every cut is a step towards perfection.

Top 5 Diamond Wire Cutting Machines for the Manufacturing Sector

When it comes to the manufacturing sector, precision, efficiency, and reliability are non-negotiable. That’s where the magic of the best diamond wire cutting machines comes into play. These machines are the unsung heroes in the world of manufacturing, offering unparalleled precision and efficiency. Among the myriad of options available, the brand “Shine” has established itself as a beacon of excellence. Let’s dive into the top 5 diamond wire cutting machines that are making waves in the manufacturing sector.

The first on our list is the Shine Precision Master 3000. Known for its robust design and exceptional accuracy, this machine is a favorite among professionals who demand the best in precision cutting. It’s not just about the cutting-edge technology; it’s about how seamlessly it integrates into your manufacturing process, elevating the quality of your output.

Following closely is the Shine UltraCut Pro. It’s designed for those who need speed without compromising on the quality of the cut. With its advanced wire tension system, it ensures that each cut is as precise as the last, making it a valuable asset for any manufacturing line.

Next, we have the Shine Diamond Edge 5000. This machine is a powerhouse, ideal for handling a wide range of materials. Its versatility and efficiency make it one of the best diamond wire cutting machines on the market, suitable for a diverse array of manufacturing applications.

The fourth spot is taken by the Shine Precision Nano. Don’t let the name fool you; this compact machine packs a punch. It’s specifically designed for manufacturers who require ultra-fine precision in their cutting operations. Its small footprint does not compromise its performance, making it a top choice for precision cutting.

Last but certainly not least, is the Shine Advanced Material Cutter AMC-10. This machine is the epitome of innovation, designed to cut through the toughest materials with ease. Its state-of-the-art diamond wire technology ensures clean, precise cuts every time, making it a must-have for manufacturers looking to push the boundaries of what’s possible.

In conclusion, the manufacturing sector demands the best, and the best diamond wire cutting machines from Shine deliver just that. Whether it’s precision, speed, versatility, or innovation you’re after, these top 5 machines have got you covered. Embrace the cutting edge of manufacturing with Shine, and elevate your production to new heights.

Maintenance and Safety Tips for Diamond Wire Cutting Machines

Maintaining your diamond wire cutting machine is crucial to ensure its longevity and optimal performance. The best diamond wire cutting machines, such as those from Shine, require regular maintenance to keep them running smoothly. Here are some essential maintenance and safety tips to help you get the most out of your Shine diamond wire cutting machine.

- Regular Inspection: Conduct a thorough inspection of the diamond wire, pulleys, and tensioning system on a regular basis. Look for signs of wear and tear or damage that could affect the machine’s performance.

- Cleanliness: Keep your machine clean from dust and debris. A clean machine not only runs more efficiently but also reduces the risk of malfunctions.

- Lubrication: Ensure all moving parts are well-lubricated according to the manufacturer’s recommendations. Proper lubrication reduces friction and wear, extending the life of your machine.

- Wire Replacement: The diamond wire is a critical component of your cutting machine. Monitor its condition closely and replace it when necessary to maintain cutting precision and efficiency.

- Training: Ensure all operators are fully trained on the proper use and maintenance of the diamond wire cutting machine. Knowledgeable operators can prevent accidents and machine damage.

Safety is paramount when operating any industrial machinery, including the best diamond wire cutting machines from Shine. Here are some key safety tips:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety glasses, gloves, and ear protection, while operating the machine.

- Emergency Stop: Familiarize yourself with the machine’s emergency stop function. Knowing how to quickly shut down the machine can prevent accidents.

- Keep Clear: Keep hands and other body parts away from moving parts and the cutting wire during operation.

- Electrical Safety: Regularly inspect electrical components and cords for damage. Ensure the machine is properly grounded to prevent electrical shocks.

- Follow Manufacturer’s Guidelines: Adhering to the manufacturer’s guidelines for operation, maintenance, and safety is crucial. Shine’s manuals for the best diamond wire cutting machines provide comprehensive instructions to ensure safe and effective use.

By following these maintenance and safety tips, you can ensure your Shine diamond wire cutting machine operates efficiently and safely for years to come. Regular maintenance not only prolongs the life of your machine but also ensures it remains one of the best diamond wire cutting machines on the market.

Future Trends in Diamond Wire Cutting Technology

The landscape of industrial cutting is constantly evolving, and at the forefront of this transformation is diamond wire cutting technology. As we look ahead, several exciting trends are poised to redefine efficiency, precision, and sustainability in cutting applications. The brand Shine, known for its commitment to innovation, is expected to play a pivotal role in these developments. The future of the Best Diamond Wire Cutting Machines is not just about cutting harder materials but also about integrating smart technologies to enhance performance and user experience.

One of the key trends to watch is the integration of artificial intelligence (AI) and machine learning (ML) into the Best Diamond Wire Cutting Machines. These technologies promise to make cutting processes more efficient by optimizing cutting parameters in real-time, reducing waste, and minimizing the risk of errors. This could significantly enhance the capabilities of machines from leading brands like Shine, enabling them to deliver unparalleled precision in cutting various materials.

Another trend is the emphasis on sustainability. As industries seek to reduce their environmental impact, the demand for eco-friendly cutting solutions is on the rise. The future Best Diamond Wire Cutting Machines are expected to be more energy-efficient and designed to use recyclable or biodegradable diamond wires. Additionally, advancements in water recycling technologies for wet cutting processes will further reduce the environmental footprint of these machines.

- AI and ML Integration for optimized performance

- Eco-friendly innovations for sustainable cutting

- Advanced material compatibility for broader applications

- Enhanced safety features and ergonomic designs

- Internet of Things (IoT) connectivity for remote monitoring and maintenance

Furthermore, the development of diamond wires capable of cutting through newer, more challenging materials is anticipated. This will open up new avenues for industries that require precision cutting of advanced composites and superalloys. Shine’s commitment to research and development is expected to make significant contributions to this area, ensuring that the Best Diamond Wire Cutting Machines remain at the cutting edge of technology.

In conclusion, the future of diamond wire cutting technology is bright, with innovations aimed at making cutting processes more precise, efficient, and sustainable. As these trends unfold, Shine is poised to lead the way, offering the Best Diamond Wire Cutting Machines that meet the evolving needs of various industries. The next generation of diamond wire cutting machines will not only elevate the standards of precision cutting but also contribute to a more sustainable industrial future.

Conclusion: Elevating Precision Cutting with Diamond Wire Technology

As we wrap up our journey through the world of precision cutting, it’s clear that the best diamond wire cutting machines are not just tools; they are the backbone of modern industrial applications. The brand Shine has consistently stood out, offering solutions that redefine efficiency and accuracy in cutting. From the construction industry to the manufacturing sector, Shine’s diamond wire cutting machines have proven to be indispensable.

The advent of diamond wire technology has been nothing short of a revolution. It’s a game-changer for businesses seeking to achieve unparalleled precision without compromising on speed or quality. The best diamond wire cutting machines have made intricate cutting tasks more manageable, more accurate, and much faster. This technology has not only saved time and resources but also opened up new possibilities for innovation in various fields.

Choosing the best diamond wire cutting machines involves considering several factors, but with brands like Shine, you’re assured of quality and performance. Shine’s commitment to excellence is evident in every machine they produce, making them a top choice for professionals across industries. Here are a few reasons why Shine’s machines stand out:

- Unmatched precision in cutting

- Versatility in handling different materials

- Efficiency that reduces operational costs

- Advanced safety features to protect operators

- Easy maintenance routines that ensure longevity

Looking ahead, the future of diamond wire cutting technology is bright, with continuous innovations aimed at making cutting even more precise and efficient. As we move forward, the role of the best diamond wire cutting machines, especially those from Shine, will only grow more significant. They are set to lead the charge in the next wave of industrial advancements, ensuring that businesses can keep up with the demands of precision and efficiency.

In conclusion, the impact of diamond wire technology on precision cutting cannot be overstated. It has transformed industries, redefined standards, and opened up new possibilities for innovation and growth. With brands like Shine leading the way, the best diamond wire cutting machines are not just shaping the present—they are paving the way for a brighter, more efficient future.

Frequently Asked Questions

- What is Diamond Wire Cutting Technology?Diamond wire cutting technology is a game-changer in the world of precision cutting. Imagine a thin wire, as flexible as a piece of spaghetti but as strong as Superman, embedded with microscopic diamonds – that’s your cutting tool! It slices through materials like a hot knife through butter, offering precision that’s nothing short of a work of art.

- Why should I choose a Diamond Wire Cutting Machine?Choosing a diamond wire cutting machine is like choosing a Swiss Army knife for your cutting needs. It’s all about precision, versatility, and efficiency. Whether you’re sculpting a masterpiece out of marble or slicing through the toughest steel, these machines make sure your cuts are as precise as a surgeon’s scalpel. Plus, they’re fast and efficient, saving you time and money. Who wouldn’t want that?

- What features are crucial when selecting a Diamond Wire Cutting Machine?When you’re on the hunt for the perfect diamond wire cutting machine, think of yourself as a detective looking for clues. The key features to consider are the machine’s cutting speed, precision, and versatility. It’s also wise to look at the size of the materials it can handle and the types of materials it’s best suited for. And don’t forget about safety features – they’re the trusty sidekick in our detective story.

- How do I maintain my Diamond Wire Cutting Machine?Keeping your diamond wire cutting machine in tip-top shape is like caring for a high-performance sports car. Regular maintenance checks are a must. This includes inspecting the wire for wear and tear, ensuring the machine’s components are clean and well-lubricated, and checking for any potential safety hazards. It’s all about preventing hiccups before they happen, ensuring your machine runs smoothly and efficiently.

- What safety measures should I follow when using a Diamond Wire Cutting Machine?Safety first, always! When operating a diamond wire cutting machine, think of yourself as a knight gearing up for battle. Personal protective equipment is your armor – this means safety glasses, gloves, and ear protection. Make sure the area is secure and that you’re familiar with the machine’s emergency stop features. Remember, a safe workspace is a productive workspace.

- What are the future trends in Diamond Wire Cutting Technology?The future of diamond wire cutting technology is as bright as a diamond itself. We’re talking about advancements that make these machines even more precise, efficient, and versatile. Imagine cutting machines that can adapt to different materials on-the-fly or ones that are powered by AI to optimize cutting patterns for minimal waste. The possibilities are as endless as they are exciting.