Are you looking to take your cutting processes to the next level? Do you want to achieve precision and efficiency in your projects? If so, diamond wire cutting services may be the solution you’re looking for. In this guide, we’ll explore the ins and outs of diamond wire cutting services, offering insights, tips, and strategies to help you optimize your cutting processes. Whether you’re new to diamond wire cutting or looking to enhance your skills, this guide has something for everyone.

Table of Contents

Introduction to Diamond Wire Cutting Services

Diamond wire cutting is a cutting-edge technique used across various industries for precise cutting of materials such as concrete, stone, and metal. It involves the use of a wire embedded with diamond particles, which ensures unparalleled precision and efficiency in cutting operations.

- Precision Cutting Solutions:

- Shine’s Diamond Wire Cutting Services offer precision cutting solutions for various materials, including concrete, stone, and metal.

- With advanced technology and expertise, Shine ensures accurate cuts with minimal wastage, enhancing the overall quality of your projects.

- Versatile Applications:

- Our Diamond Wire Cutting Services cater to a wide range of industries, from construction to manufacturing.

- Whether it’s shaping architectural elements or cutting industrial components, Shine’s services adapt to diverse cutting needs.

- Efficiency and Productivity:

- Shine prioritizes efficiency and productivity in all its Diamond Wire Cutting Services.

- By utilizing cutting-edge equipment and techniques, we streamline cutting processes, saving you time and resources.

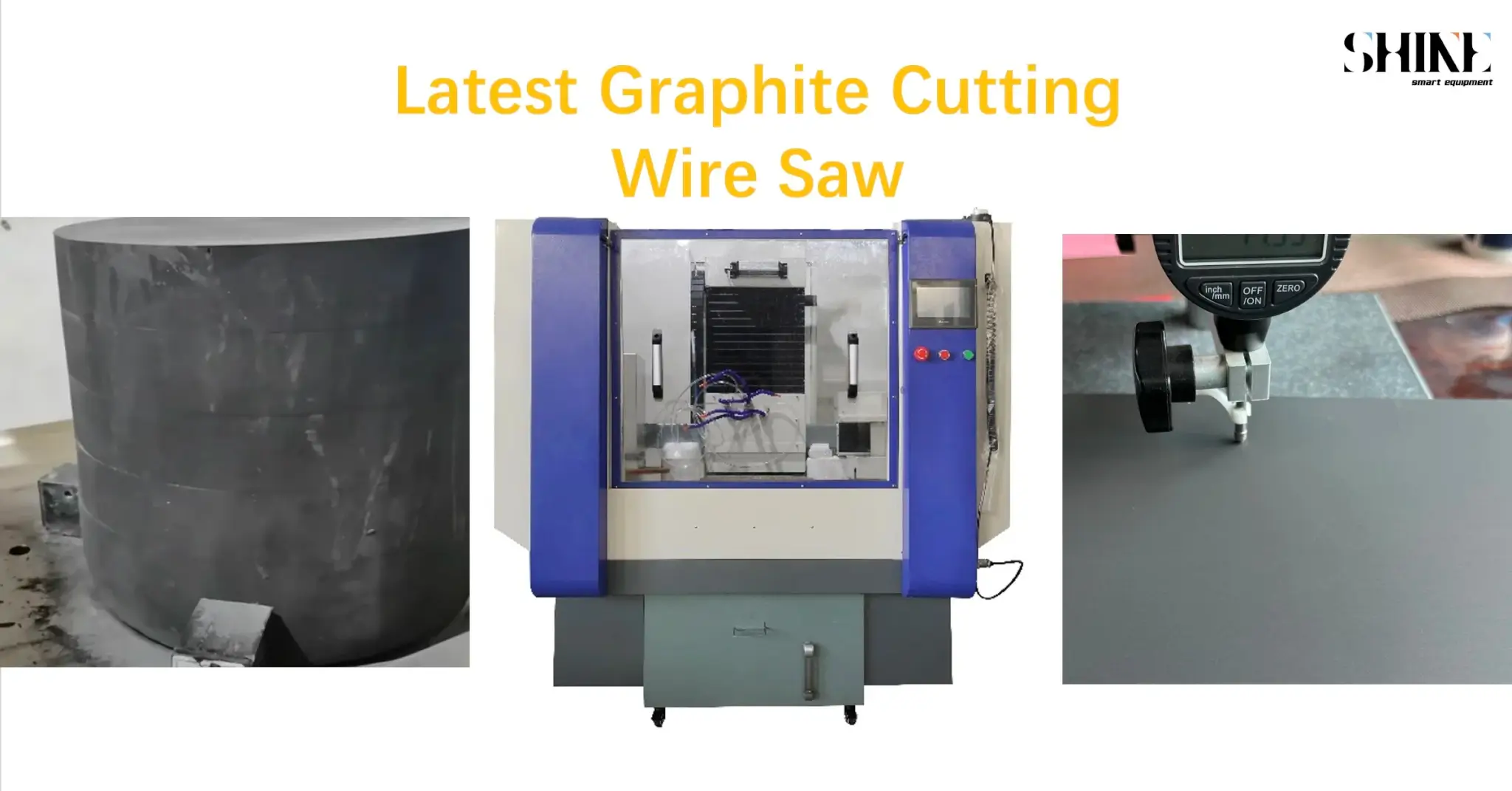

- Advanced Equipment and Technology:

- We invest in state-of-the-art equipment and technology to ensure optimal performance and results.

- Shine’s Diamond Wire Cutting Services utilize the latest advancements in diamond wire technology for superior cutting capabilities.

- Safety and Reliability:

- Safety is paramount in Shine’s Diamond Wire Cutting Services, with strict adherence to safety protocols and regulations.

- Clients can trust Shine to deliver reliable cutting solutions while maintaining a safe working environment for all involved.

- Tailored Solutions:

- Shine offers tailored Diamond Wire Cutting Services to meet the unique requirements of each project.

- Whether it’s a small-scale renovation or a large-scale construction project, we customize our services to fit your specific needs.

- Commitment to Excellence:

- With a dedication to excellence, Shine strives to exceed client expectations in every aspect of its Diamond Wire Cutting Services.

- From project planning to execution, we are committed to delivering unparalleled quality and customer satisfaction.

Advantages of Diamond Wire Cutting

Diamond wire cutting offers several advantages over conventional cutting methods:

- Precision Cutting:

- Diamond wire cutting services offer unparalleled precision, ensuring exact cuts with minimal deviation.

- The use of diamond particles on the wire’s surface enables precise control over the cutting process, resulting in accurate dimensions and shapes.

- This precision is crucial for industries where tight tolerances and high-quality finishes are paramount, such as aerospace and automotive manufacturing.

- Versatility and Adaptability:

- Shine’s diamond wire cutting services are highly versatile, capable of cutting through a wide range of materials including concrete, stone, and metal.

- Whether it’s intricate designs in marble sculptures or straight cuts in reinforced concrete beams, Shine’s diamond wire cutting services can adapt to various cutting requirements.

- This versatility makes Shine an ideal choice for industries with diverse cutting needs, offering a one-stop solution for all cutting challenges.

- Efficiency and Productivity:

- Shine’s diamond wire cutting services are renowned for their efficiency, allowing for rapid and streamlined cutting processes.

- With advanced equipment and expertise, Shine’s technicians can complete cutting tasks quickly, reducing project timelines and labor costs.

- Increased productivity translates to cost savings and faster project delivery, making Shine the preferred choice for time-sensitive projects.

- Minimal Material Wastage:

- Diamond wire cutting minimizes material wastage by providing clean and precise cuts, reducing the need for additional finishing processes.

- The use of diamond particles ensures smooth cutting edges, minimizing material loss and maximizing yield.

- This eco-friendly approach aligns with sustainability goals, making Shine’s diamond wire cutting services not only efficient but also environmentally responsible.

- Enhanced Safety:

- Shine prioritizes safety in all its operations, including diamond wire cutting services.

- With strict adherence to safety protocols and guidelines, Shine ensures a safe working environment for its technicians and clients.

- Advanced safety features and regular training sessions contribute to accident prevention, giving clients peace of mind knowing that their projects are in safe hands.

- Quality Assurance:

- Shine maintains rigorous quality control measures throughout the diamond wire cutting process, ensuring consistent and reliable results.

- From material selection to final inspection, Shine’s commitment to quality shines through in every cut.

- Clients can trust Shine to deliver exceptional quality and craftsmanship, meeting and exceeding their expectations every time.

Achieve Precision and Efficiency with Diamond Wire Cutting Services | Shine

Elevate your cutting projects with our state-of-the-art Diamond Wire Cutting Services. From concrete to metal, our services offer precision and efficiency for superior results. Explore the benefits of diamond wire cutting services and revolutionize your projects today.

Applications of Diamond Wire Cutting

Diamond wire cutting finds applications in various industries, including:

- Construction Industry:

- Cutting concrete structures, beams, and columns with precision and efficiency.

- SHINE’s diamond wire cutting services ensure smooth and accurate cuts for construction projects of all sizes.

- Mining Sector:

- Extracting mineral resources from hard rock formations using advanced diamond wire cutting techniques.

- SHINE’s expertise in mining applications ensures optimal results and increased productivity.

- Manufacturing Processes:

- Precision cutting of metal components and parts for various industries, including aerospace and automotive.

- SHINE’s diamond wire cutting services offer versatility and adaptability to meet the diverse cutting needs of manufacturing sectors.

- Civil Engineering Projects:

- Controlled demolition and dismantling of structures with minimal environmental impact.

- SHINE’s commitment to safety and efficiency makes it the preferred choice for civil engineering projects requiring diamond wire cutting solutions.

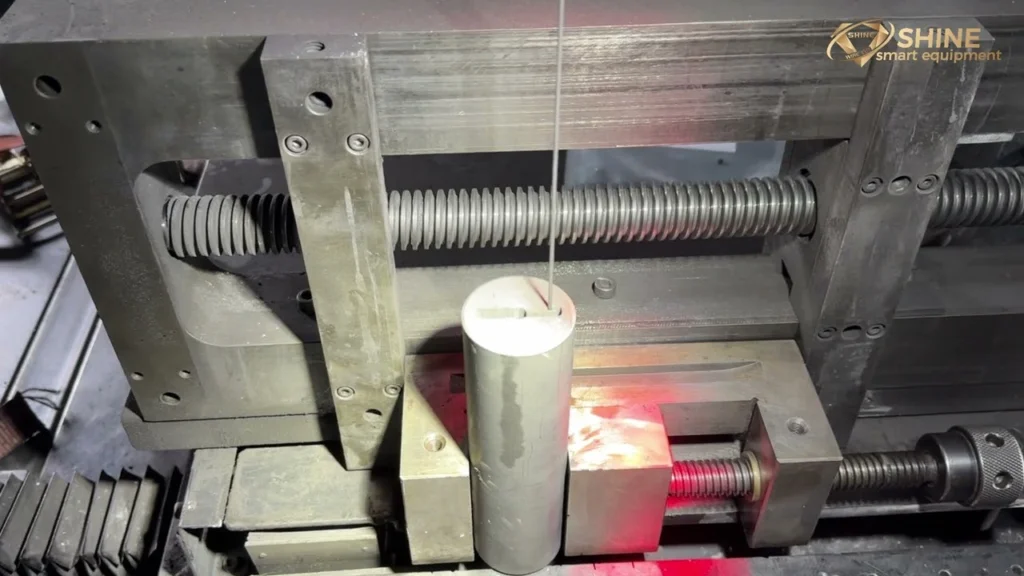

Process of Diamond Wire Cutting

The process of diamond wire cutting involves the following steps:

- Preparation: Assessing the material to be cut and selecting the appropriate diamond wire and cutting equipment.

- Setup: Securing the workpiece and configuring the cutting equipment for optimal performance.

- Cutting: Initiating the cutting process using the diamond wire, ensuring steady and controlled movement to achieve the desired cut.

- Finishing: Inspecting the cut for accuracy and making any necessary adjustments to ensure the desired outcome.

Choosing the Right Diamond Wire Cutting Service Provider

Selecting the right diamond wire cutting service provider is crucial for achieving optimal results:

- Experience: Look for a provider with extensive experience in diamond wire cutting and a proven track record of successful projects.

- Equipment: Ensure that the provider uses state-of-the-art equipment and cutting-edge technology for efficient and precise cutting.

- Safety: Prioritize providers who adhere to strict safety protocols and guidelines to minimize risks and ensure a safe working environment.

- Reputation: Consider the reputation and credibility of the service provider by reviewing client testimonials and feedback.

Mastering Diamond Wire Cutting Services: Expert Insights and Tips | Shine

Explore the world of diamond wire cutting services with our informative video tutorial. Join us as we delve into the process, benefits, and applications of diamond wire cutting services, offering expert insights and practical tips for maximizing performance and results. Watch now to unlock the full potential of diamond wire cutting services.

Safety Measures in Diamond Wire Cutting

Safety is paramount in diamond wire cutting operations:

- Personal Protective Equipment (PPE): Ensure that all personnel involved in the cutting process wear appropriate PPE, including safety glasses, helmets, and gloves.

- Training: Provide comprehensive training to operators on the safe use of diamond wire cutting equipment and techniques.

- Risk Assessment: Conduct a thorough risk assessment before commencing cutting operations to identify potential hazards and implement preventive measures.

- Emergency Preparedness: Have emergency procedures in place, including protocols for handling accidents or equipment failures.

Conclusion

Diamond wire cutting services offer a cutting-edge solution for precision cutting of various materials in diverse industries. By understanding the process, advantages, applications, and safety measures associated with diamond wire cutting, businesses can harness its potential to streamline operations and achieve superior results.

FAQS

What is diamond wire cutting?

Diamond wire cutting is a precision cutting technique that utilizes a wire embedded with diamond particles to cut through various materials such as concrete, stone, and metal. It offers superior accuracy and efficiency compared to traditional cutting methods.

What are the advantages of diamond wire cutting?

Diamond wire cutting offers several advantages, including precision, versatility, efficiency, minimal material wastage, and enhanced safety. It allows for precise cuts with minimal deviation, adapts to various materials and shapes, streamlines cutting processes, reduces material wastage, and prioritizes safety in operations

What industries can benefit from diamond wire cutting services?

Diamond wire cutting services are beneficial for a wide range of industries, including construction, mining, manufacturing, civil engineering, and more. It is used for cutting concrete structures, extracting mineral resources, shaping metal components, and various other applications across different sectors.

How does diamond wire cutting work?

Diamond wire cutting works by using a wire embedded with diamond particles that are pulled through the material to be cut under tension. The abrasive nature of the diamond particles allows the wire to slice through the material with precision, resulting in clean and accurate cuts

Is diamond wire cutting safe?

Yes, diamond wire cutting is considered safe when performed by trained professionals following strict safety protocols. Proper safety measures, including the use of personal protective equipment (PPE) and adherence to safety guidelines, ensure a secure working environment and minimize risks associated with the cutting process

What factors should I consider when choosing a diamond wire cutting service provider?

When selecting a diamond wire cutting service provider, consider factors such as their experience, equipment, safety protocols, reputation, and ability to provide tailored solutions. Choose a provider like Shine that has a proven track record, utilizes advanced technology, prioritizes safety, and offers customized cutting solutions to meet your specific needs.