Introduction

The use of Diamond Wire Saw Cutting Machines in the industrial sector has been growing rapidly as demands for precision cutting have increased. This modern technology has significantly improved material processing capabilities and revolutionized cutting tasks across various industries. SHINE, one of the leading Suppliers and Manufacturers of these machines, is at the forefront of this innovation. In this article, we will delve into how SHINE’s Diamond Wire Cutting Machine have become the industrial cutting edge.

The Evolution of Diamond Wire Saw Cutting Machines

Before the invention of diamond wire saw cutting machines, traditional methods were used for material processing. These methods included using hand tools, such as chisels and hammers, or large saws that were not only time-consuming but also produced rough cuts and wasted materials. With the emergence of diamond wire saw cutting machines, a new era in industrial cutting began.

More Videos please go into the Youtube

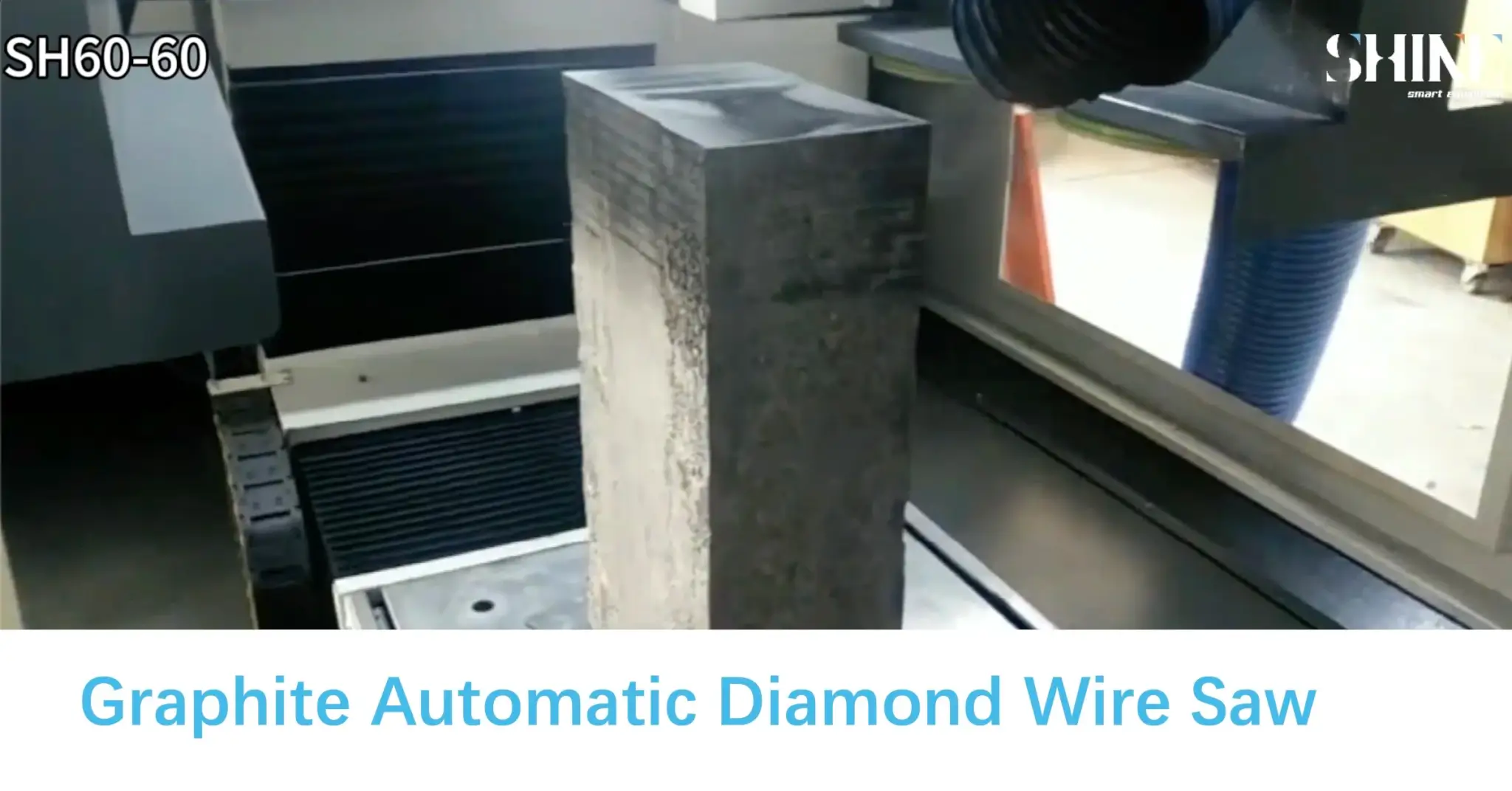

At first, these machines were only used for stone and marble cutting. However, with advancements in technology and the discovery of new diamond wire formulas, these machines now have the capabilities to cut through various materials such as metal, concrete, glass, and even composites.

SHINE has been at the forefront of this evolution, continuously improving and innovating their diamond wire saw cutting machines to meet the ever-changing needs of different industries.

Table of Contents

Basic Principles of Diamond Wire Saw Cutting

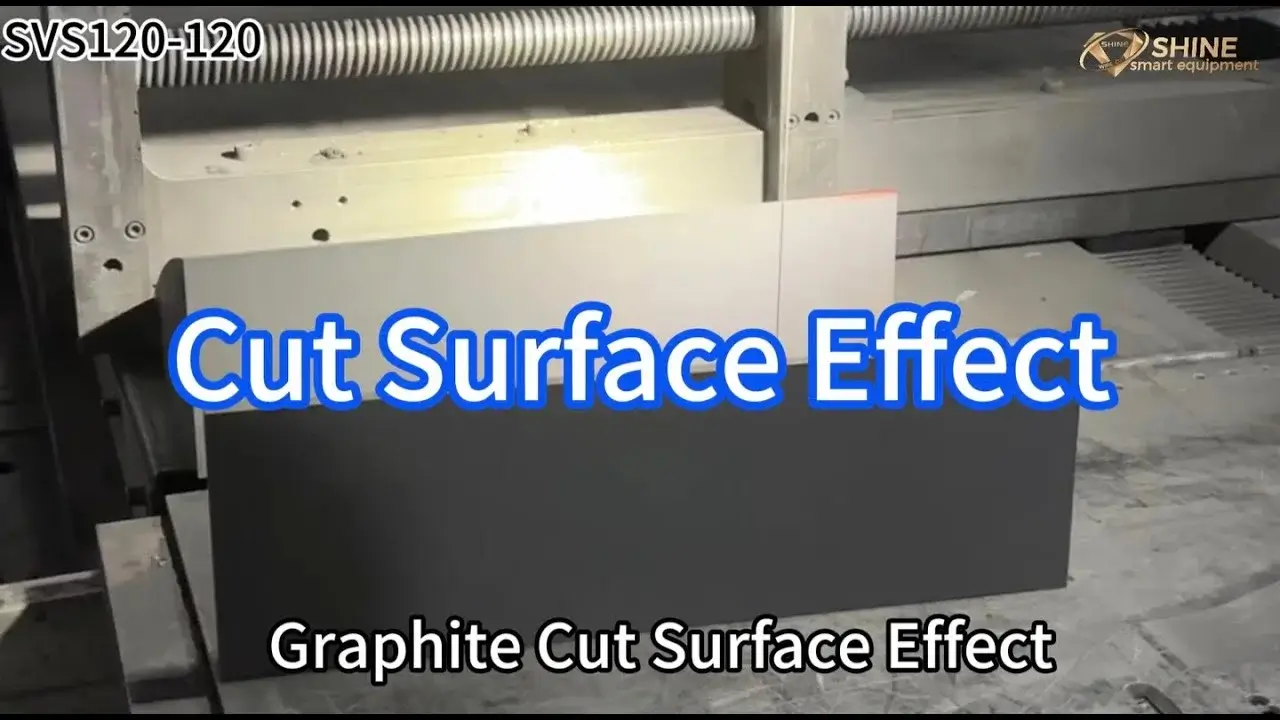

Diamond wire saws epitomize cutting prowess, combining speed with exactitude. The secret lies in their operation: a wire embedded with diamonds saws through hard materials with unmatched precision. Diamonds, nature’s hardest substance, make it possible to slice through granite, quartz, and even reinforced concrete. Here, we dive into how these technical marvels operate and what lies at their core—their cutting edge.

Components of a Diamond Wire Saw Cutting Machine

SHINE has worked tirelessly to refine each component of their cutting machines. From innovatively designed wire saws to highly efficient tensioning systems, SHINE’s commitment to excellence is conspicuous. Let’s dissect the machine’s anatomy, where SHINE has sculpted its competitive niche in the diamond wire cutting market.

Wire Saw

The heart of any wire saw machine is its wire, a looping strand fitted with diamond segments. SHINE’s unique approach in creating superior wires lies in the optimal bond between the diamond segments and the wire, designed for longer life and endurance.

Driving System

A robust driving system is critical for consistent cutting. While competitors vary in motor types, SHINE chooses industry-preferred options to ensure reliability. The speed and power behind each cut can define the finish — and SHINE’s choices strive to lead the pack.

Control System

At the helm of operation is the control system. SHINE’s integrated controls are user-friendly and precise, providing operators with the ability to adjust cutting parameters effortlessly, directly impacting the machine’s productive output.

Tensioning System

SHINE’s innovative tensioning technology ensures optimal wire tension, crucial for the accuracy of cuts while extending the life of the wire. This is where SHINE pulls away from the competition with its durable and reliable tensioning designs.

Cooling and Lubrication System

Efficient cooling and lubrication preserve the wire and prevent premature wear. SHINE has developed systems that stand out in the market for their effectiveness in maintaining ideal cutting conditions, thus ensuring the longevity of the machine’s components.

Comparative Analysis of Different Brands

When placed side-by-side with competitors, SHINE’s diamond wire saw cutting machines exhibit clear advantages. We take a closer look at these edge-defining factors and validate their impact through customer testimonials and industry feedback.

- SHINE’s diamond wire saw machines offer superior efficiency and precision compared to other methods of cutting.

- The use of diamonds in the wire ensures exceptional cutting capabilities, even through hard materials like granite and reinforced concrete.

- SHINE has continuously improved its machine components, resulting in an impeccable reputation for quality and reliability.

- SHINE’s proprietary wire bonding method extends the life of the wire and enhances its endurance.

- The choice of industry-preferred motors in the driving system ensures consistent cutting speed and power.

- SHINE’s control system is user-friendly and precise, allowing operators to easily adjust cutting parameters for optimal productivity.

- The innovative tensioning technology employed by SHINE guarantees accurate cuts while prolonging the life of the wire.

- SHINE’s cooling and lubrication system effectively maintains ideal cutting conditions, preserving the longevity of the machine’s components.

- Customer testimonials and industry feedback further validate SHINE’s superiority in the market.

Types of Diamond Wire Saw Cutting Machines

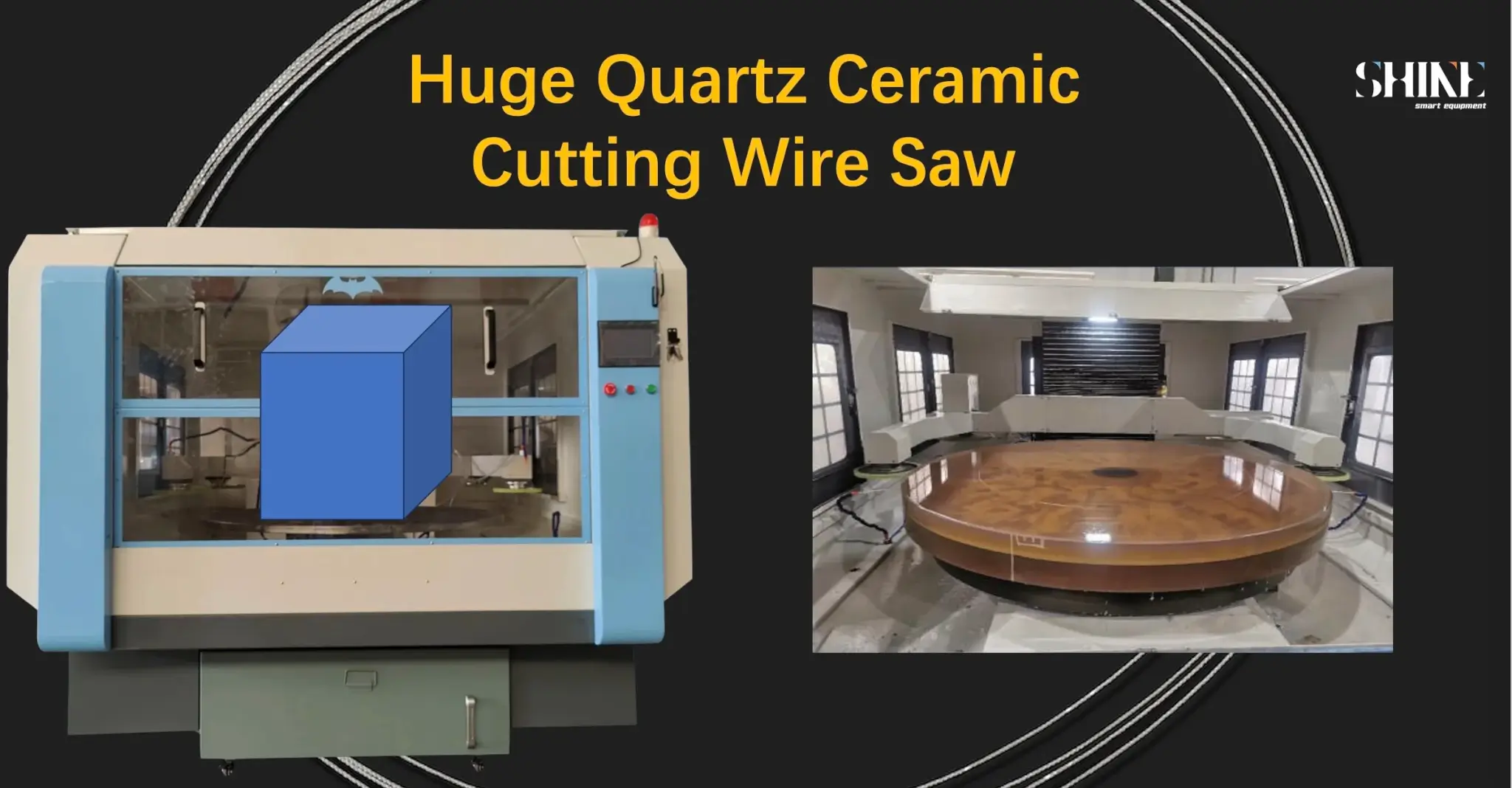

Whether it’s a colossal stationary unit suitable for factory settings or a nimble portable saw for on-site applications, SHINE’s range stands tall against the competition. Specialized machines catering to niche industries highlight SHINE’s commitment to market trends and customer needs.

- SHINE offers a range of diamond wire saw cutting machines suitable for various industries.

- Their machines come in different sizes and capabilities, from small portable units to large stationary ones.

- SHINE’s machines are designed to cater to specific needs and trends in the market.

- They offer specialized machines for niche industries, showcasing their adaptability and commitment to customer needs.

Advantages of Diamond Wire Saw Cutting with SHINE

When it comes to precision cutting, SHINE’s diamond wire saw machines lead the pack. With a strong emphasis on efficiency and operator safety, SHINE’s machines are at the forefront of the industry.

- Precision: SHINE’s diamond wire saw cutting machines offer unparalleled precision in material processing. The use of high-quality diamonds in the wire ensures precise cuts, even through hard materials like granite and reinforced concrete.

- Efficiency: SHINE’s machines are designed for maximum efficiency, resulting in less material wastage and increased productivity. This translates to cost savings for customers and a quicker turnaround time.

- Operator Safety: SHINE prioritizes operator safety by implementing advanced control systems that allow operators to easily adjust cutting parameters. Furthermore, their tensioning technology and cooling system ensure ideal cutting conditions for prolonged use.

- Quality and Reliability: SHINE has earned a reputation for consistently delivering high-quality machines that are reliable and long-lasting. With continuous improvements to machine components, customers can trust in the durability of SHINE’s diamond wire saw cutting machines.

- Customization Options: SHINE offers a range of diamond wire saw cutting machines to cater to various industries and their specific needs. From small portable units to large stationary ones, SHINE has a machine that can meet any cutting requirement.

- Industry Recognition: With positive customer testimonials and industry feedback, SHINE’s superiority in the market is undeniable. Customers can trust in the performance and reliability of SHINE’s machines, backed by industry recognition and satisfaction.

Overall, SHINE’s diamond wire saw cutting machines offer unparalleled precision, efficiency, and operator safety. With a commitment to quality and the ability to cater to various industries, SHINE is the top choice for all material processing needs. Experience the industrial cutting edge with SHINE’s diamond wire saw cutting machines.

Why Choose Us? The Trusted Suppliers of Cutting Edge Technology

At SHINE, we understand that precision, efficiency, and safety are crucial factors when it comes to material processing. That’s why our diamond wire saw machines are designed to exceed your expectations in all these aspects. With a strong commitment to quality, we continuously innovate and improve our technology to provide the best cutting solution for various industries.

But what sets SHINE apart from other cutting machine manufacturers? Apart from our top-notch performance, we also offer unparalleled customer service and support. Our team of experts is always ready to assist you and provide customized solutions to meet your specific cutting needs.

Plus, with our machines’ ability to cut through a wide range of materials, you can streamline your production process and increase efficiency. And with operator safety being our top priority, you can rest assured that our machines are designed with the highest safety standards in mind.

In summary, SHINE’s diamond wire saw cutting machines offer a winning combination of cutting-edge technology, quality, and customer support. So why settle for anything less?

Operational Considerations

Every machine needs proper setup, maintenance, and occasionally troubleshooting. SHINE simplifies these aspects with intuitive design, transparent maintenance processes, and comprehensive support and warranty policies, making their machines as user-friendly as they are effective.

- SHINE’s machines require proper setup and maintenance for optimal performance.

- Their designs are user-friendly, making it easier for operators to understand and operate the machines.

- They have transparent maintenance processes in place, ensuring that customers know what to expect when it comes to upkeep and repairs.

- SHINE offers comprehensive support and warranty policies for their machines.

- This ensures peace of mind for customers, knowing that they can count on SHINE’s assistance whenever needed.

- With intuitive design and reliable support, SHINE’s machines are not only effective but user-friendly as well.

Safety Measures

Safety is a top priority when it comes to operating any type of machinery, and diamond wire saw cutting machines are no exception. SHINE recognizes the potential hazards involved in using their machines and has implemented strict safety measures to ensure the well-being of operators and those working around them.

- Safety measures are essential when operating any machinery, including diamond wire saw cutting machines.

- SHINE prioritizes safety and has implemented strict measures to protect operators and those around them.

- These measures include proper training for operators, as well as warning signs and labels on the machine itself.

- SHINE also emphasizes the importance of wearing appropriate protective gear when operating their machines.

- With these safety measures in place, SHINE’s diamond wire saw cutting machines provide a safe and efficient cutting experience.

Applications in Various Industries

Diamond wire saw cutting machines have a wide range of applications in various industries. From construction and mining to manufacturing and even art restoration, these machines provide precise and efficient cutting solutions for a variety of materials. With SHINE’s innovative technology and commitment to customer needs, their diamond wire saw cutting machines have become go-to tools for many industries, making them an essential asset for businesses around the world.

- Construction: SHINE’s diamond wire saw cutting machines are commonly used for cutting through building materials such as concrete, stone, and steel.

- Mining: In the mining industry, these machines are utilized for various tasks such as extracting mineral deposits or creating openings in mines.

- Manufacturing: Diamond wire saw cutting is also useful in manufacturing processes, especially in the production of ceramics, glass, and other hard materials.

- Art restoration: The precision and delicacy of SHINE’s machines make them ideal for restoring ancient artifacts or sculptures made of delicate materials such as marble or porcelain.

- With their versatility and efficiency, SHINE’s diamond wire saw cutting machines have become essential in various industries, providing innovative solutions for cutting hard materials. So no matter what industry you’re in, SHINE has a machine to meet your specific cutting needs. Trust SHINE for all your material processing requirements and see the difference their machines can make.

Technological Advancements and SHINE’s Innovations

As technology continues to advance, the diamond wire saw cutting industry is constantly evolving, and SHINE is at the forefront of this innovation. With their commitment to pushing the boundaries and setting new standards for precision cutting, SHINE has introduced various technological advancements in their machines that have revolutionized the industry. From enhanced cutting performance to improved safety measures, SHINE’s innovations have solidified their position as a leader in the diamond wire saw cutting market.

- SHINE’s machines incorporate advanced technology to improve cutting performance and accuracy.

- Their tensioning technology ensures optimal wire tension for precise cuts and extended wire lifespan.

- The cooling and lubrication system maintains ideal cutting conditions, preserving machine components.

- SHINE also prioritizes safety with features such as automatic wire break detection and emergency stop buttons.

- These technological advancements have not only improved cutting efficiency but also increased operator safety, making SHINE’s machines a top choice in the industry.

Future of Diamond Wire Saw Cutting

The future of diamond wire saw cutting is constantly evolving, with new technologies and techniques emerging regularly. As a company dedicated to innovation, SHINE continues to push the boundaries and invest in research and development to stay at the forefront of this industry. With a focus on sustainability, efficiency, and safety, SHINE’s future machines are expected to be even more advanced, providing solutions for new cutting challenges across various industries.

- As technology continues to advance, diamond wire saw cutting is expected to become even more precise and efficient.

- SHINE is committed to staying ahead of the curve and investing in research and development for future machine advancements.

- Sustainability will also play a significant role, with SHINE’s machines incorporating eco-friendly practices such as utilizing recycled water for cooling and lubrication.

- The increasing demand for automation and remote control capabilities may also be incorporated into future designs, making diamond wire saw cutting even more convenient and efficient.

- With SHINE’s dedication to innovation and customer satisfaction, the future of diamond wire saw cutting looks promising. So whether you’re in construction, mining, or any other industry that requires precision cutting, trust SHINE for all your current and future cutting needs. Play a vital role in the success of your business with SHINE’s advanced technology and unmatched cutting capabilities. Keep an eye out for SHINE’s future developments, and stay ahead of the competition with their revolutionary machines.

Escalating the precision and quality of industrial cutting requires meticulous examination and understanding of the tools at our disposal. As we’ve demonstrated, SHINE’s diamond wire saw cutting machines mark an uncompromising stance on performance, safety, and user satisfaction. With an emphasis on robust design and technological innovation, SHINE is not merely advancing with the market—they’re leading the charge.

Are you looking to integrate unsurpassed cutting efficiency and exactness into your operations? Delve no further. Contact us today to receive personalized machine recommendations that cater to your unique manufacturing needs. With SHINE, begin redefining your precision manufacturing experience.

FAQS

Q: What is a diamond wire saw cutting machine?

A: A diamond wire saw cutting machine is an industrial tool used for precise cutting of hard materials such as concrete, stone, and steel. SHINE is a leading manufacturer of these machines, providing innovative solutions for various industries.

Q: How does SHINE ensure precision in their diamond wire saw cutting machines?

A: SHINE incorporates advanced technology in their machines, such as tensioning and cooling systems, to ensure optimal wire tension and cutting conditions for precise cuts. This results in high-quality performance and accuracy in cutting.

Q: Can diamond wire saw cutting machines be used in the manufacturing industry?

A: Yes, they can. In fact, SHINE’s diamond wire saw cutting machines have become essential in precision manufacturing processes, providing unmatched cutting efficiency and exactness for various materials.

Q: Are SHINE’s diamond wire saw cutting machines eco-friendly?

A: Yes, they are. SHINE prioritizes sustainability and has incorporated features in their machines that utilize recycled water for cooling and lubrication purposes. This reduces environmental impact and promotes eco-friendly practices.

Q: How does SHINE prioritize safety in their diamond wire saw cutting machines?

A: SHINE’s machines are equipped with features such as automatic wire break detection and emergency stop buttons to ensure operator safety. They also have robust designs and undergo rigorous testing to meet safety standards.

Q: Can SHINE provide personalized recommendations for diamond wire saw cutting machines?

A: Yes, they can. With their expertise in the industry, SHINE’s team can assess your manufacturing needs and provide personalized recommendations for the best diamond wire saw cutting machine that fits your requirements. With SHINE, you can trust in their commitment to customer satisfaction and unmatched cutting capabilities.

Ready to elevate your cutting processes with SHINE’s advanced diamond wire saw cutting machines?

Contact us today to learn more about our innovative solutions and receive personalized recommendations for your business needs. Trust in SHINE’s expertise and commitment to excellence for all your cutting needs. Join the ranks of satisfied customers and experience the difference with SHINE. Let us help you shine brighter in your industry.

So, what are you waiting for? Contact us now and let’s start cutting towards a brighter future with SHINE. Stay ahead of the game and stay on top with our revolutionary machines. Together, we can elevate your business to new heights.