In the rapidly evolving world of technology, precision is paramount. Enter the stage, quartz wire sawing, a game-changer in the manufacturing of optical and electronic components. This technique, powered by the latest advancements in wire cutting machines, including the diamond wire cutting machine and diamond wire saw machine, is revolutionizing how materials are processed. At the heart of this transformation is the brand Shine, leading the charge in pushing the boundaries of what’s possible with quartz wire sawing.

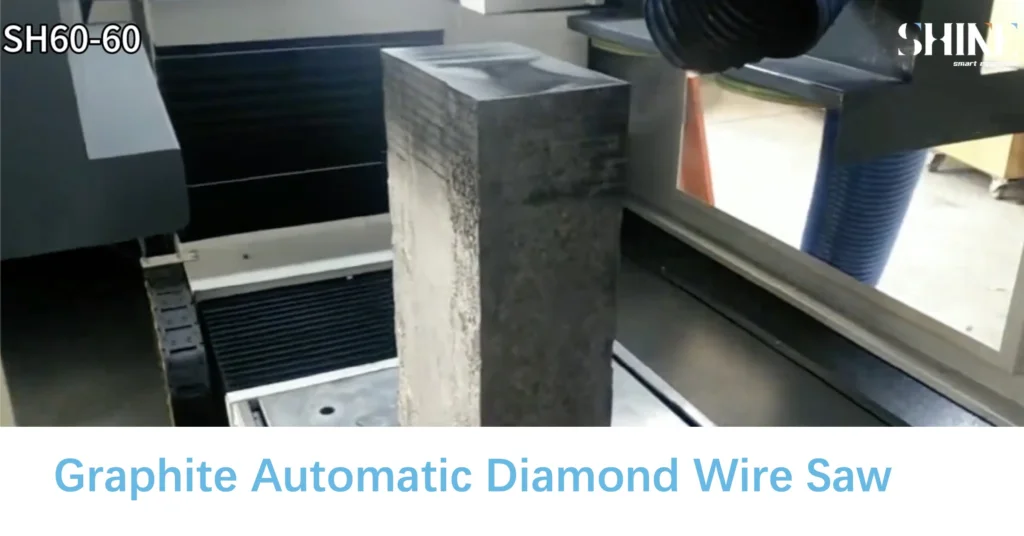

The mechanics behind these wire saw machines are as fascinating as they are complex. By utilizing a metal wire coated with industrial-grade diamond particles, these machines achieve cuts with precision that was once deemed unattainable. The diamond wire cutting machine, in particular, offers a level of accuracy that makes it indispensable in the creation of intricate components required in the optics and electronics industries. It’s not just about making cuts; it’s about sculpting the future, one micron at a time.

Why does this matter for industries like optics and electronics? The answer lies in the unparalleled precision and efficiency that quartz wire sawing brings to the table. High-quality lenses, semiconductors, and other critical components can now be manufactured with minimal material wastage, thanks to the precision cutting capabilities of the diamond wire saw machine. This technique ensures that even the most complex shapes are cut to exact specifications, thereby significantly enhancing the performance and reliability of optical and electronic devices.

When compared to traditional cutting methods, the advantages of quartz wire sawing are clear. Traditional methods often fall short in terms of precision, efficiency, and the ability to minimize waste. On the other hand, the diamond wire cutting machine not only excels in these areas but also opens up new possibilities for complex shapes that were previously impossible to achieve. This represents a significant leap forward in manufacturing capabilities, setting a new standard for what’s possible in the design and production of optical and electronic components.

Looking ahead, the future of quartz wire sawing technology appears bright, with ongoing developments aimed at further increasing speed, efficiency, and versatility. As these wire cutting machines become even more advanced, we can expect to see their application extend beyond optics and electronics, potentially revolutionizing other industries as well. The brand Shine is at the forefront of these innovations, continuously pushing the envelope of what’s possible with quartz wire sawing. The implications for manufacturing, design, and technological advancement are immense, promising a future where the limitations of today become the breakthroughs of tomorrow.

Introduction to Quartz Wire Sawing

At the heart of the most groundbreaking advancements in optics and electronics lies a surprisingly elegant and precise technology: quartz wire sawing. This method, which has significantly evolved over the years, employs the use of a wire cutting machine, specifically a diamond wire cutting machine or diamond wire saw machine, to slice through quartz with remarkable accuracy. The essence of this technique is not just in the cutting itself, but in the ability to maintain the integrity of quartz, a material paramount to the Shine brand’s commitment to quality and innovation.

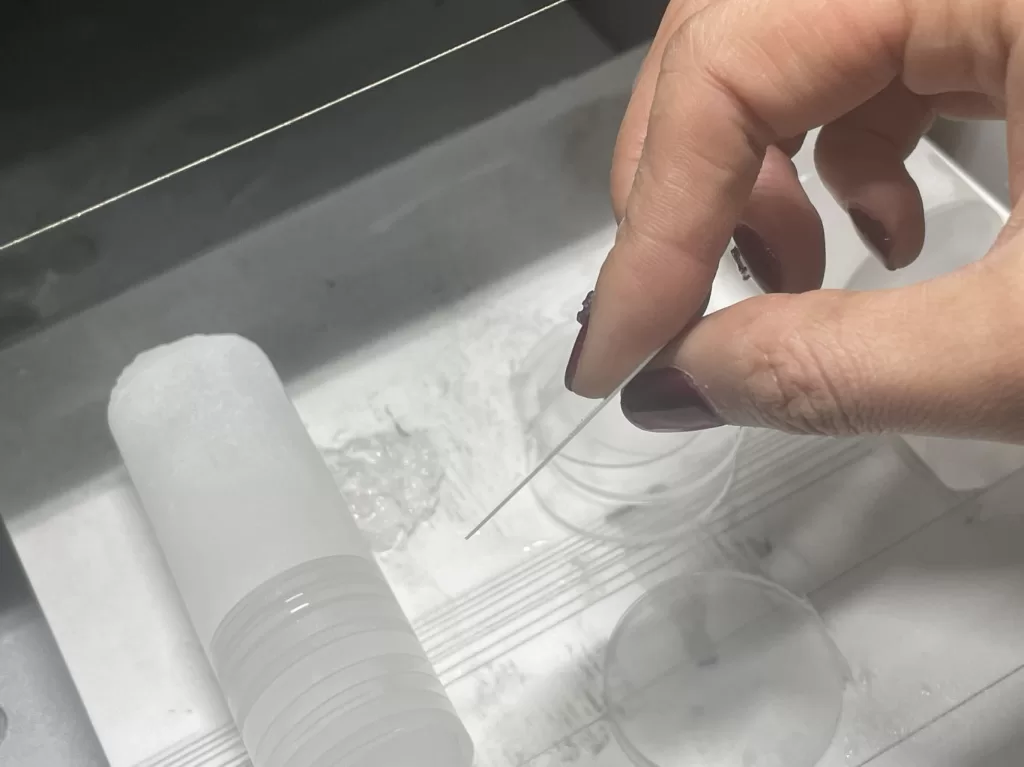

The diamond wire saw machine, a cornerstone in the Shine toolkit, leverages a metal wire embedded with diamond particles to achieve its cutting prowess. This isn’t just any wire; it’s a meticulously designed component that embodies the fusion of durability and precision. The wire’s coated diamonds act as cutting teeth, slicing through quartz with minimal resistance, thereby reducing material waste and ensuring that each cut is as clean as it is precise.

What sets quartz wire sawing apart from traditional cutting methods is not only its precision but also its versatility. The wire cutting machine’s ability to maneuver through quartz allows for the creation of complex shapes and sizes, which are often required in the highly demanding fields of optics and electronics. This adaptability makes the diamond wire saw machine an invaluable asset in the production of high-quality lenses, semiconductors, and other critical components.

The evolution of wire sawing technology, particularly within the Shine brand, has been driven by a relentless pursuit of perfection. Continuous improvements in diamond wire technology, machine efficiency, and cutting techniques have enabled Shine to stay at the forefront of the industry. As we look to the future, the potential for further advancements in wire sawing technology is boundless, promising even greater precision, efficiency, and applications that could extend well beyond optics and electronics.

In conclusion, the introduction of quartz wire sawing has been nothing short of revolutionary for the optics and electronics industries. With the Shine brand’s commitment to excellence and innovation, the diamond wire cutting machine has become an essential tool in shaping the future of technology. As we continue to push the boundaries of what’s possible, quartz wire sawing stands as a testament to the power of precision engineering and its pivotal role in driving technological progress.

The Mechanics of Wire Saw Machines

The heart of the quartz wire sawing process lies within the remarkable mechanics of wire saw machines. These sophisticated pieces of equipment, including the wire cutting machine, diamond wire cutting machine, and diamond wire saw machine, are engineered to perform precise cuts on one of the hardest materials on earth: quartz. At the core of their functionality is a metal wire, not just any wire, but one that is meticulously coated with diamond particles. This is where the brand Shine steps into the spotlight, offering machines that are not only reliable but also embody the pinnacle of cutting-edge technology.

The operation of a wire saw machine is both elegant and efficient. The diamond-coated wire is threaded through a series of guides and pulleys, creating a continuous loop that moves at high speed. As the wire makes contact with the quartz, the abrasive action of the diamond particles grinds away material, cutting through the quartz with precision that traditional cutting methods can hardly match. This process is incredibly versatile, allowing for the production of intricate shapes and sizes that are crucial for the optics and electronics industries.

One of the standout features of Shine’s wire saw machines is their adaptability. These machines can be adjusted for tension and speed, ensuring that the cutting process is optimized for different thicknesses and types of quartz. This level of control is instrumental in minimizing material wastage and maximizing efficiency, making Shine’s wire saw machines a preferred choice for manufacturers seeking to push the boundaries of what’s possible in optics and electronics fabrication.

Furthermore, the environmental aspect of Shine’s diamond wire saw machines cannot be overlooked. Unlike some traditional cutting methods that generate significant waste and potentially harmful dust, wire sawing with diamond-coated wires produces minimal waste and is a cleaner process. This not only benefits the environment but also contributes to a safer working environment for operators.

In conclusion, the mechanics behind wire saw machines, particularly those from Shine, represent a blend of precision, efficiency, and innovation. These machines are at the forefront of quartz cutting technology, offering solutions that are indispensable for the future of the optics and electronics industries. With advancements in diamond wire technology and machine design, Shine’s wire cutting machines are set to remain essential tools in the manufacturing landscape.

Applications in Optics and Electronics

The realm of optics and electronics has been revolutionized by the advent of quartz wire sawing, a technology that allows for the precise cutting of materials to create components with unparalleled accuracy. At the heart of this innovation is the wire cutting machine, particularly those that utilize diamond wire, such as the diamond wire cutting machine or diamond wire saw machine. These machines, championed by brands like Shine, have become indispensable in the manufacturing processes of various optical and electronic devices.

One of the primary applications of quartz wire sawing in the optics industry is in the production of high-quality lenses. These lenses are used in a wide range of products, from cameras and microscopes to telescopes and eyeglasses. The precision of the diamond wire saw machine ensures that each lens offers the clarity and performance expected by consumers and professionals alike. Furthermore, the ability to cut intricate shapes with minimal material wastage means that even the most complex lens designs can be realized efficiently and cost-effectively.

In the electronics sector, quartz wire sawing plays a critical role in the creation of semiconductors. Semiconductors are the backbone of virtually all modern electronics, found in everything from smartphones and computers to appliances and automotive systems. The wire cutting machine’s precision is crucial here, as it allows for the cutting of silicon wafers into the thin slices required for semiconductor production. The accuracy and efficiency of the diamond wire cutting machine not only enhance the performance of these components but also contribute to the overall sustainability of manufacturing practices by reducing material waste.

Beyond lenses and semiconductors, quartz wire sawing is instrumental in producing a variety of other critical components in optics and electronics. These include but are not limited to, optical fibers used in telecommunications, quartz glass for scientific instruments, and intricate parts for electronic devices. Each application benefits from the specific advantages offered by the diamond wire saw machine, such as its ability to produce smooth, precise cuts at high speeds, making Shine’s technology a cornerstone in the advancement of these industries.

As we look to the future, the applications of quartz wire sawing in optics and electronics are only set to expand. With ongoing advancements in diamond wire saw machine technology, driven by innovators like Shine, we can expect to see even more complex and miniature components being produced. This will not only enhance the capabilities of optical and electronic devices but also open up new possibilities for how we use and interact with technology in our daily lives.

Advantages Over Traditional Cutting Methods

When it comes to shaping the future of optics and electronics, the precision and efficiency of quartz wire sawing stand out, particularly when utilizing state-of-the-art equipment like the wire cutting machine, diamond wire cutting machine, and diamond wire saw machine from Shine. These innovative tools have revolutionized manufacturing processes, offering a suite of advantages over traditional cutting methods that cannot be overlooked. Let’s delve into what makes quartz wire sawing the preferred choice for industry professionals.

First and foremost, the precision achievable with a diamond wire saw machine is unparalleled. Traditional cutting methods often struggle to maintain consistency, especially when working with materials as delicate as quartz. The diamond-coated wire used in these machines allows for cuts that are not only incredibly accurate but also leave behind a smoother finish, reducing the need for extensive post-cut processing. This precision is critical in industries where even the smallest deviation can compromise the functionality of the component, such as in optics and electronics.

Another significant advantage is the reduction in material wastage. Traditional cutting techniques, by their nature, can be quite wasteful due to their lack of precision and the potential for material breakage during the cutting process. The Shine diamond wire cutting machine, on the other hand, uses a thin, diamond-coated wire that makes it possible to cut closely packed patterns without sacrificing material. This efficiency is not only cost-effective but also aligns with the growing industry and consumer demand for more sustainable manufacturing practices.

Furthermore, the versatility of the diamond wire saw machine allows for the cutting of complex shapes that would be challenging, if not impossible, to achieve with conventional cutting methods. This capability opens up new design possibilities, enabling manufacturers to push the boundaries of innovation in product development. Whether it’s intricate components for electronic devices or complex geometries for optical applications, the wire cutting machine from Shine provides the flexibility needed to meet these demanding requirements.

Lastly, the speed of cutting with modern wire saw machines is a game-changer. Traditional methods can be painstakingly slow, creating bottlenecks in the production process. The efficiency of the Shine diamond wire cutting machine not only accelerates production times but also ensures that high-quality standards are maintained, even when operating at increased speeds. This combination of speed and quality is essential for staying competitive in the fast-paced world of optics and electronics manufacturing.

In conclusion, the advantages of quartz wire sawing with Shine’s wire cutting machine, diamond wire cutting machine, and diamond wire saw machine over traditional cutting methods are clear. From unparalleled precision and reduced material wastage to the ability to cut complex shapes and fast production times, these innovative tools are setting new standards in the manufacturing of optical and electronic components. As we look to the future, it’s evident that the role of quartz wire sawing in advancing these industries will only continue to grow.

Future Trends in Quartz Wire Sawing Technology

As we delve into the future trends of quartz wire sawing technology, it’s evident that innovation and efficiency are at the forefront. The brand Shine, synonymous with quality and precision in the realm of wire cutting machines, is leading the charge towards revolutionizing this field. The advancements in diamond wire cutting machine technology are not just about enhancing the speed; they’re about redefining the precision with which we can shape the future of optics and electronics.

One of the most anticipated trends in this sector is the development of even more refined diamond wire saw machines. These machines are expected to offer unparalleled accuracy, allowing for even more intricate designs and shapes to be cut from quartz. This is particularly crucial for industries where the smallest discrepancy can lead to significant functional discrepancies. The efficiency of these machines is also expected to see a notable increase, reducing the time required for cutting without compromising on quality.

Another exciting development is the integration of AI and machine learning into the wire cutting process. This integration promises to bring about a new era of precision and customization. By analyzing vast amounts of data, these intelligent systems can optimize cutting patterns and parameters for each unique piece of quartz, ensuring that material wastage is minimized and productivity is maximized. Shine is at the forefront of incorporating these technologies into their diamond wire saw machines, setting a new standard for the industry.

Environmental sustainability is also a key focus for future trends in quartz wire sawing technology. As industries across the globe strive for greener manufacturing processes, the demand for wire cutting machines that consume less energy and produce fewer waste materials is on the rise. Innovations such as improved diamond wire designs and cutting techniques that reduce the need for coolant fluids are steps in the right direction, aligning with the global push towards sustainability.

In conclusion, the future of quartz wire sawing technology is bright, with advancements aimed at increasing precision, efficiency, and environmental sustainability. Shine, with its commitment to innovation and quality, is poised to lead the way in these developments. The evolution of diamond wire cutting machines and the integration of cutting-edge technologies promise to further elevate the capabilities of industries reliant on quartz components, ensuring that the optics and electronics sectors continue to thrive and expand.

Frequently Asked Questions

- What is Quartz Wire Sawing?Quartz wire sawing is a cutting-edge technique that uses a thin wire impregnated with diamond particles to precisely cut through quartz. This method is celebrated for its precision, allowing the creation of intricate shapes and sizes in the manufacturing of optical and electronic components. It’s a game-changer in industries where accuracy is paramount.

- How does a Wire Saw Machine work?Imagine a fine metal wire, as flexible as a piece of thread but tough, coated with diamond particles – the hardest material out there. This wire is then threaded through a series of guides and pulleys, creating a loop that moves at high speed. When this wire is pressed against quartz, it slices through with precision, thanks to the abrasive action of the diamond particles. It’s like cutting through butter with a hot knife, but on a much more sophisticated level.

- Why is Quartz Wire Sawing preferred over traditional cutting methods?Quartz wire sawing is like the Swiss Army knife of cutting techniques; it’s versatile, precise, and leaves minimal waste behind. Traditional methods often involve more direct contact, which can lead to material loss and less accuracy. With wire sawing, the ability to cut complex shapes without compromising the integrity of the quartz is a significant advantage, making it the go-to choice for industries that demand perfection.

- What are the applications of Quartz Wire Sawing in Optics and Electronics?This technique is not just cutting-edge; it’s shaping the future. In optics, it’s used to create lenses that are clearer and more precise than ever before. In electronics, it helps in manufacturing semiconductors and other components with unparalleled accuracy. If you’ve ever marveled at the clarity of a camera lens or the efficiency of your smartphone, you’ve seen quartz wire sawing’s handiwork.

- What future developments are expected in Wire Sawing Technology?Hold on to your hats because the future of wire sawing technology is looking explosive. Imagine machines that are faster, more efficient, and capable of even greater precision. We’re talking about advancements that could open up new applications in industries we haven’t even thought of yet. The potential for innovation is as vast as it is exciting, promising to revolutionize how we think about manufacturing and technology.