Have you ever pondered the intricate journey a rough sapphire undergoes to emerge as a meticulously cut gemstone, embodying both beauty and precision? The art of sapphire wire cutting, a pivotal process in this transformation, combines technological prowess with the delicate touch of craftsmanship. SHINE’s cutting-edge methods and equipment, including state-of-the-art gemstone cutting machines and diamond wire cutting machines, set a new standard in the industry. But what makes their technique stand out in the realm of gemstone processing?

Diving deeper into the world of sapphire wire cutting, one cannot help but marvel at the precision and efficiency that SHINE brings to the table. Their innovative approach not only enhances the beauty of these gemstones but also maximizes their potential in various applications. As we explore this comprehensive guide, let’s uncover the secrets behind SHINE’s unmatched proficiency and how their advanced equipment is shaping the future of sapphire cutting.

Table of Contents

Sapphire, a material renowned for its exceptional durability and clarity, has found its way into the heart of numerous industries ranging from electronics to luxury watchmaking. The process of shaping and cutting this gemstone, however, requires a technology that matches its robustness and precision. Enter the realm of sapphire wire cutting, a technique that has revolutionized the way we manipulate one of the hardest materials known to man. This guide delves deep into the intricacies of sapphire wire cutting, exploring its methods, applications, and the cutting-edge advancements that continue to push the boundaries of what’s possible.

Introduction

Overview of Sapphire as a Material

Sapphire, a corundum variety, is second only to diamond in its hardness, making it a prized material not only in jewelry but also in industrial applications. Its remarkable physical and chemical properties, including high thermal and electrical insulating qualities, make it indispensable in various sectors.

Importance of Sapphire in Various Industries

From the screens of our smartphones to the watch faces that endure daily wear, sapphire’s presence is ubiquitous. Its application in the aerospace, defense, and semiconductor industries underlines its versatility and the critical role it plays in modern technology.

Introduction to Wire Cutting Technology

Wire cutting technology, a method traditionally associated with metals, has evolved to accommodate the cutting of gemstones like sapphire. This technique offers unparalleled precision, making it ideal for the intricate demands of various applications.

Understanding Sapphire

Physical and Chemical Properties of Sapphire

Sapphire’s extraordinary hardness (9 on the Mohs scale) is just the beginning. Its optical clarity, high melting point, and resistance to chemical attacks make it an ideal candidate for a myriad of applications.

Why Sapphire? Its Use Cases Across Industries

Sapphire’s use cases span from protective covers for electronics, optical windows in laser surgeries, to the clear, durable faces of luxury watches. Its adoption across industries speaks volumes about its unparalleled qualities.

Sapphire in the Tech Industry: From Electronics to Watches

In the tech industry, sapphire’s role cannot be overstated. It serves as a protective layer for sensors and cameras, and its application in LED technology and semiconductor wafers showcases its versatility and indispensability.

The Basics of Wire Cutting

What is Wire Cutting?

Wire cutting involves using a thin wire as a cutting tool, often coated with diamond or another abrasive substance, to slice through materials with precision.

Evolution of Wire Cutting Technologies

The technology has progressed from basic mechanical cutting to sophisticated methods that include electrical discharge machining (EDM) and laser-assisted cutting, enhancing the precision and efficiency of the process.

Types of Wire Cutting Machines

Wire cutting machines vary from traditional models to advanced ones like the gemstone cutting machine and the diamond wire cutting machine, each designed to meet specific needs in the cutting process.

Sapphire Wire Cutting: A Deep Dive

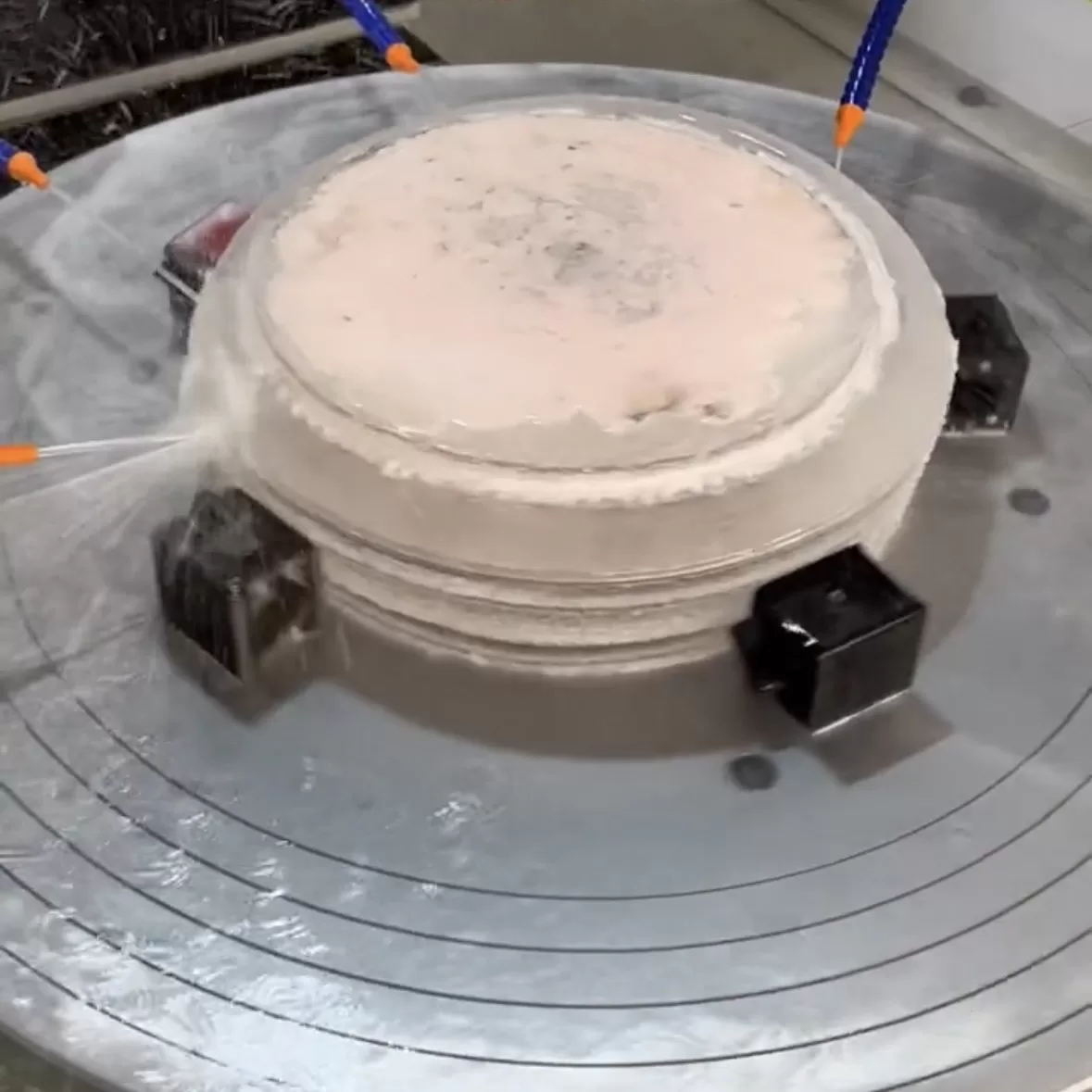

The Process of Sapphire Wire Cutting

This process involves guiding a wire, imbued with abrasive particles, through the sapphire in a controlled manner to achieve precise cuts with minimal waste.

Equipment and Tools Used in Sapphire Wire Cutting

Key equipment includes the wire cutting machine, tensioning systems to maintain wire stability, and cooling systems to mitigate the heat generated during cutting.

Advantages of Wire Cutting for Sapphire

Wire cutting offers unmatched precision, minimal material loss, and the ability to cut complex shapes, making it the preferred method for sapphire processing.

Technical Challenges and Solutions

Common Challenges in Sapphire Wire Cutting

Challenges include managing the wire’s wear and tear, controlling the thermal impact on sapphire, and maintaining precision in cuts.

Innovations Addressing These Challenges

Recent innovations include improved wire compositions for extended life, laser-assisted cutting for enhanced precision, and advanced cooling techniques to minimize thermal damage.

Ensuring Precision and Minimizing Waste

Technological advancements and refined cutting techniques have significantly improved precision and reduced material wastage in sapphire wire cutting.

Sapphire Wire Cutting Techniques

Dry Cutting vs. Wet Cutting: A Comparison

While dry cutting is less messy and quicker, wet cutting offers better cooling and dust management, making it more suitable for sapphire cutting.

Laser-Assisted Wire Cutting for Sapphire

Laser-assisted cutting represents a leap in precision and efficiency, allowing for cleaner cuts and reduced mechanical stress on the sapphire.

Recent Advances in Sapphire Wire Cutting Technology

Advances include automated wire tension control, improved wire materials for longer life and better cutting performance, and integration of AI for precision control.

Quality Control in Sapphire Wire Cutting

Importance of Quality Control

Quality control ensures that the final product meets the stringent standards required in industries that depend on sapphire components.

Techniques for Ensuring High-Quality Cuts

These include real-time monitoring of the cutting process, post-cut inspection with microscopes, and the use of software for dimensional analysis.

Quality Control Equipment and Software

Equipment such as high-resolution cameras and software for 3D modeling and analysis play crucial roles in maintaining the high standards of sapphire wire cutting.

Sapphire Wire Cutting Applications

Electronics: Semiconductors and LED Manufacturing

In electronics, sapphire substrates are essential for the production of LEDs, and its insulating properties make it perfect for semiconductor devices.

Watchmaking: Sapphire Crystal Faces

The luxury watch industry values sapphire for its clarity and scratch resistance, making it the material of choice for watch faces.

Aerospace and Defense: High-Durability Components

Sapphire’s durability and resistance to environmental extremes make it ideal for aerospace and defense applications, where reliability is paramount.

Environmental and Safety Considerations

Environmental Impact of Sapphire Wire Cutting

While sapphire wire cutting is relatively efficient, efforts are ongoing to reduce its environmental impact through better waste management and recycling.

Safety Measures and Equipment for Operators

Safety measures include protective equipment, adequate ventilation, and training to handle the machines safely, ensuring a secure working environment.

Reducing Waste and Recycling Efforts

Initiatives to reduce waste include recycling sapphire dust for secondary uses and optimizing cutting patterns to minimize material loss.

Cost Analysis and Economic Impact

Cost Factors in Sapphire Wire Cutting

Key factors include the cost of the wire, energy consumption, and the efficiency of the cutting process, all of which impact the overall cost-effectiveness.

Economic Benefits of Efficient Sapphire Wire Cutting

Efficient cutting techniques not only reduce material waste but also lower production costs, contributing to the economic viability of sapphire applications.

Case Studies: Cost Savings and Efficiency Improvements

Case studies highlight the benefits of adopting advanced wire cutting technologies, showcasing significant savings and efficiency gains in various industries.

Future Trends in Sapphire Wire Cutting

Emerging Technologies and Their Potential

Emerging technologies, including AI and machine learning, promise to further enhance precision, reduce waste, and streamline the sapphire cutting process.

The Role of AI and Automation in Wire Cutting

AI and automation are set to revolutionize sapphire wire cutting by optimizing cutting paths, predicting machine maintenance, and improving cut quality.

Predictions for the Sapphire Industry

The sapphire industry is expected to continue growing, with wire cutting technologies playing a pivotal role in meeting the increasing demand for precision-cut sapphire.

Industry Insights and Expert Opinions

Insights from industry experts underscore the continuous evolution of wire cutting technologies and their critical importance in expanding the applications of sapphire.

Case Studies: Success Stories in Sapphire Wire Cutting

Success stories from leading companies illustrate the transformative impact of advanced wire cutting techniques on productivity and product quality.

Challenges and Opportunities for the Future

While challenges remain, the future of sapphire wire cutting is bright, with ongoing innovations promising to overcome existing limitations and open new possibilities.

Getting Started with Sapphire Wire Cutting

How to Choose the Right Wire Cutting Equipment

Choosing the right equipment involves considering the material to be cut, the desired precision, and the production volume, among other factors.

Training and Skill Development for Operators

Proper training ensures that operators can maximize the capabilities of wire cutting machines, enhancing both safety and productivity.

Finding Suppliers and Service Providers

Selecting reputable suppliers and service providers is crucial for obtaining quality wire cutting machines and ensuring reliable after-sales support.

Maintaining Your Sapphire Wire Cutting Equipment

Routine Maintenance Tips

Regular maintenance, including wire replacement, tension adjustments, and system calibration, is essential for optimal performance.

Troubleshooting Common Issues

Understanding common issues, such as wire breakage or uneven cuts, and knowing how to address them quickly, minimizes downtime.

Upgrading and Modifying Equipment for Better Performance

Upgrades and modifications can enhance the capabilities of wire cutting machines, accommodating new materials and cutting techniques.

Legal and Regulatory Framework

Regulations Affecting Sapphire Wire Cutting

Adhering to regulations and standards is essential for ensuring the safety and environmental sustainability of the wire cutting process.

Compliance and Certification for Equipment

Compliance with international standards and obtaining necessary certifications ensure the reliability and safety of wire cutting equipment.

International Standards and Best Practices

Following international standards and best practices not only enhances product quality but also fosters trust and reliability in the industry.

Conclusion

Recap of Key Points

Sapphire wire cutting stands as a testament to the blend of art and science, bringing precision to the forefront of material processing.

The Future Outlook for Sapphire Wire Cutting

With continuous advancements and an unwavering demand for precision, the future of sapphire wire cutting looks promising, driven by innovation and technological progress.

Final Thoughts on the Importance of Innovation in the Field

Innovation remains the cornerstone of progress in sapphire wire cutting, ensuring that this critical technology keeps pace with the evolving demands of the industries it serves.

For authoritative insights into Sapphire Wire Cutting technologies and the science behind gemstone cutting, visit Gemological Institute of America (GIA), a leading source for gemstone research and education. This link provides a wealth of information on cutting-edge practices in the gemstone industry, supporting the innovative approaches used by SHINE in sapphire cutting.

As we’ve journeyed through the intricate world of Sapphire Wire Cutting, it’s clear that SHINE stands at the forefront of innovation and excellence. Their expertise in utilizing cutting-edge gemstone and diamond wire cutting machines transforms raw sapphires into marvels of precision and beauty. This guide has offered a glimpse into the art and science that SHINE brings to the gemstone cutting industry, setting new benchmarks for quality and efficiency.

If you’re as captivated by the potential of precision-cut sapphires as we are, there’s never been a better time to explore SHINE’s offerings. Discover how their advanced sapphire wire cutting techniques and equipment can elevate your projects. Click to learn more and embark on a journey of discovery with SHINE’s gemstone cutting solutions today.

FAQs

- What is Sapphire Wire Cutting? Sapphire Wire Cutting is a precise method used by SHINE to slice through sapphire gemstones with unmatched accuracy, utilizing specialized wire cutting machines.

- How does SHINE’s technology differ from traditional cutting methods? SHINE employs advanced gemstone cutting machines and diamond wire cutting technology, offering superior precision and reduced waste compared to conventional methods.

- Can SHINE’s wire cutting technique be applied to other gemstones? Yes, SHINE’s versatile wire cutting technology is not only perfect for sapphires but can also be adapted for other gemstones, ensuring precision across a variety of materials.

- What makes SHINE a leader in Sapphire Wire Cutting? SHINE’s commitment to innovation, along with their use of cutting-edge diamond wire cutting machines, sets them apart as a leader in the sapphire cutting industry.

- How does Sapphire Wire Cutting by SHINE benefit the end-user? End-users enjoy higher quality, precisely cut sapphires with minimal waste, enhancing the value and beauty of the final product, thanks to SHINE’s meticulous cutting process.

- Where can I learn more about SHINE’s Sapphire Wire Cutting services? To discover more about SHINE’s exceptional sapphire wire cutting services and how they can benefit your projects, visit their website and explore their range of solutions.